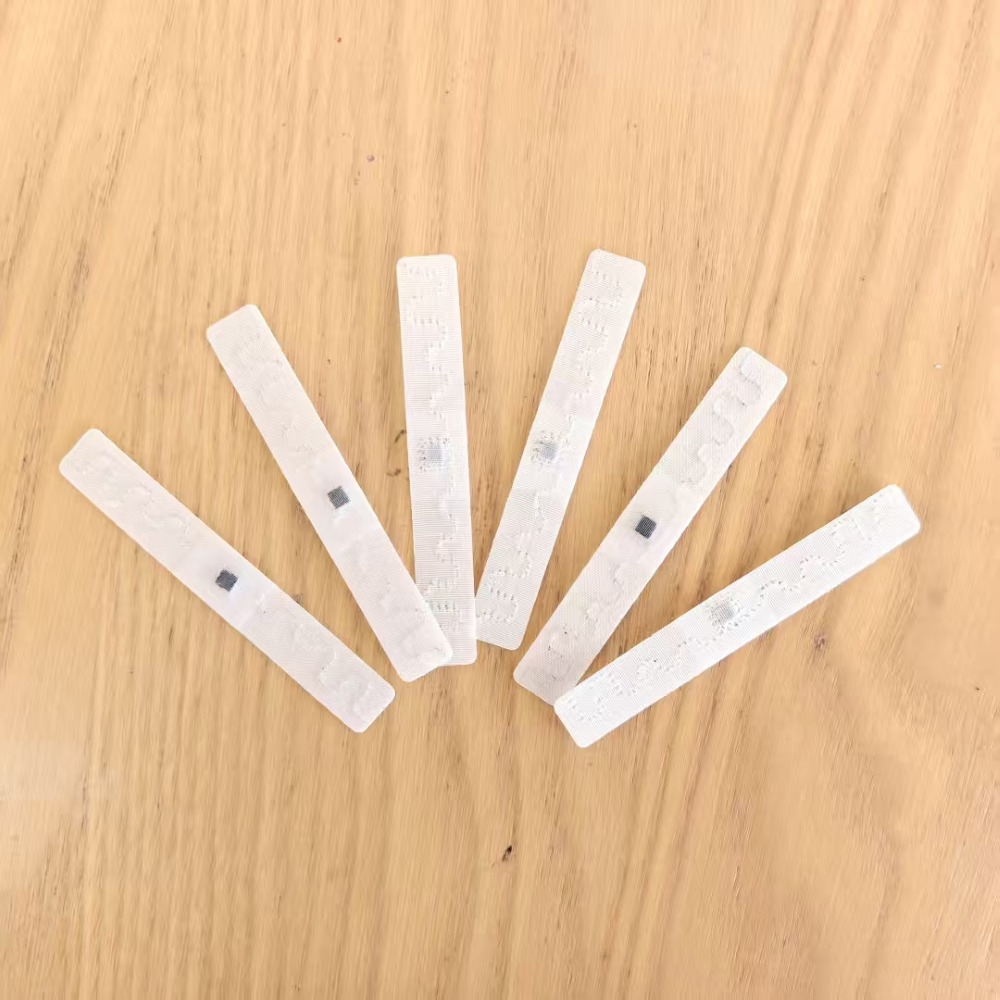

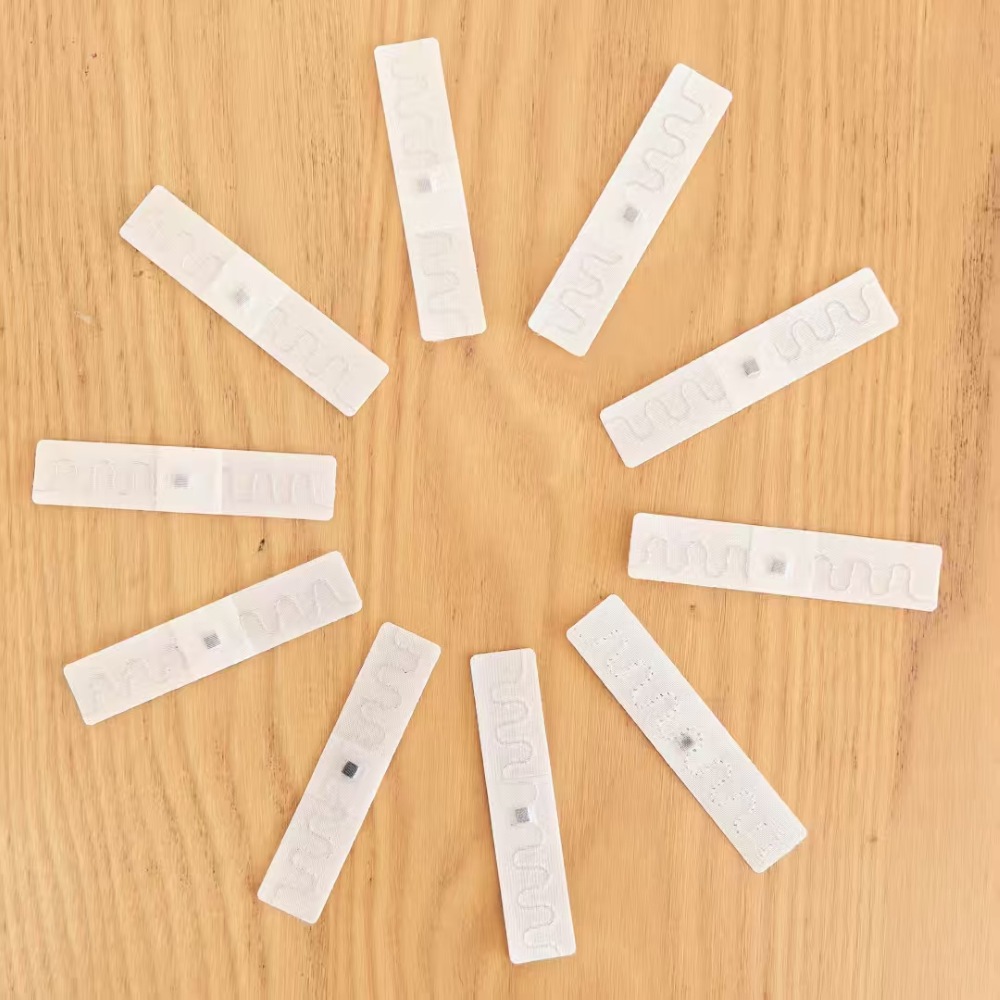

The Industrial Laundry and Textile Rental industry faces a constant battle: maximizing the lifespan of high-value linens while minimizing loss and operational inefficiencies. Traditional manual counting and barcode systems are error-prone and labor-intensive, leading to significant financial bleed. However, a new standard in RFID-driven lifecycle management is emerging, set by the TT7015 industrial UHF RFID laundry tag.

This isn't just another tag; it's a ruggedized data carrier engineered to survive the most punishing environments. Built with a flexible antenna encapsulated in woven polyester, the TT7015 laundry tag is specifically designed to withstand over 200 industrial wash cycles. This endurance is tested against extreme conditions: high-pressure extraction up to 60 bars, wash temperatures of 90°C (194°F), and even the chemical assault of oxygenated bleach and alkaline detergents. For healthcare linen management, its ability to endure medical autoclave sterilization at 135°C (275°F) makes it a game-changer for tracking surgical drapes and gowns without compromising sterile processing protocols.

A critical differentiator often overlooked is its non-metallic, needle-detection-safe construction. Unlike tags with metal components, the TT7015 laundry tag will not trigger needle detectors in hospitals or hotels, eliminating a major source of sorting delays and operational friction. This seamless integration is vital for infection control and efficient workflow in large-scale facilities.

The technological backbone of this solution is the NXP UCODE 9xe chip, compliant with the EPC Gen 2 (ISO 18000-6C) standard. This chip provides a robust 128-bit EPC memory bank for storing unique identifiers and delivers exceptional read sensitivity. Laundries can achieve read ranges exceeding 14 meters with fixed readers mounted above conveyor systems, enabling high-speed, fully automated sortation of thousands of items per hour. Handheld readers can inventory a full cart of linens in seconds from over 9.5 meters away, revolutionizing stocktake efficiency.

The Solution in Action: From Soiled to Sterile

The implementation of a textile lifecycle management system powered by these tags follows a seamless process:

Tagging: Each linen item is fitted with a sewn-in Hydro LA421 tag.

Soiled Collection: RFID gates at soiled linen drop-off points automatically record returns, reconciling against issued inventory.

Wash Process: The tags are read at various stages to monitor cycle completion and track wash count.

Automated Sortation: Clean linens are automatically sorted on conveyor systems based on their RFID data, directly into carts destined for specific floors, wings, or clients.

Sterile Distribution: In hospitals, tags are read again upon entry to the Central Sterile Supply Department (CSSD) and after autoclaving.

Usage & Analytics: Data on wash cycles, lifespan, and loss rates are fed into a cloud-based platform, enabling predictive replacement and powerful ROI analytics.

For hotel linen management, this translates to a drastic reduction in loss (often 15-25% of inventory annually) and the elimination of tedious manual counts. For healthcare providers, it ensures the integrity of sterile linen packs and provides a verifiable chain of custody.

The TT7015 laundry tag represents more than a product; it's a pivotal component in the digital transformation of textile management, offering a proven path to operational transparency, significant cost savings, and unparalleled control over asset lifecycle.

Related searching:Industrial UHF RFID laundry tag, healthcare linen management, healthcare infection control, 200 wash cycle RFID tag, medical autoclave sterilization, needle-detection safe RFID, textile lifecycle management, hotel linen tracking, automated laundry sortation, RFID for rental textile, NXP UCODE 9xe, Central Sterile Supply Department (CSSD), healthcare linen management