T5030LA fast inventory RAIN RFID label

The Logistics Accelerator: Verify More, Scan Faster, Ship Smarter.

It introduces dynamic-tuned antenna geometry specifically optimized for high-velocity logistics operations. Its enhanced multi-tag response algorithm achieves >800 tags/sec—surpassing conventional labels by 30%—enabling unprecedented throughput in three critical domains:

• EPC Gen2 / ISO 18000-63 Protocol compatible

• GS1-128 Barcode + EPC Encodable

• Works with WMS integration (SAP, Oracle, Manhattan)

• Compatible with RFID printers of different brands

• Reduced shipping label scanning labor by 70%

? Logistics & Transportation Dominance

Real-Time Trailer Loading Verification

Scan 200+ pallets in 45 seconds with 99.98% ASN accuracy

Seal Integrity Monitoring

Tamper-evident tagging for security-sensitive shipments

Intermodal Container Auto-ID

Reduce cross-dock handoff time by 70% via rail-to-truck RFID tunnels

? Warehouse Revolution

RFID-Driven Put-Wall Sorting

Process 4,500 items/hour (vs. 1,200 manual)

Deadstock Identification & Removal

Auto-flag stagnant inventory with date-encoded EPCs

Hands-Free Cycle Counting

Complete 100,000-SKU inventories in 2 hours (traditional: 3 weeks)

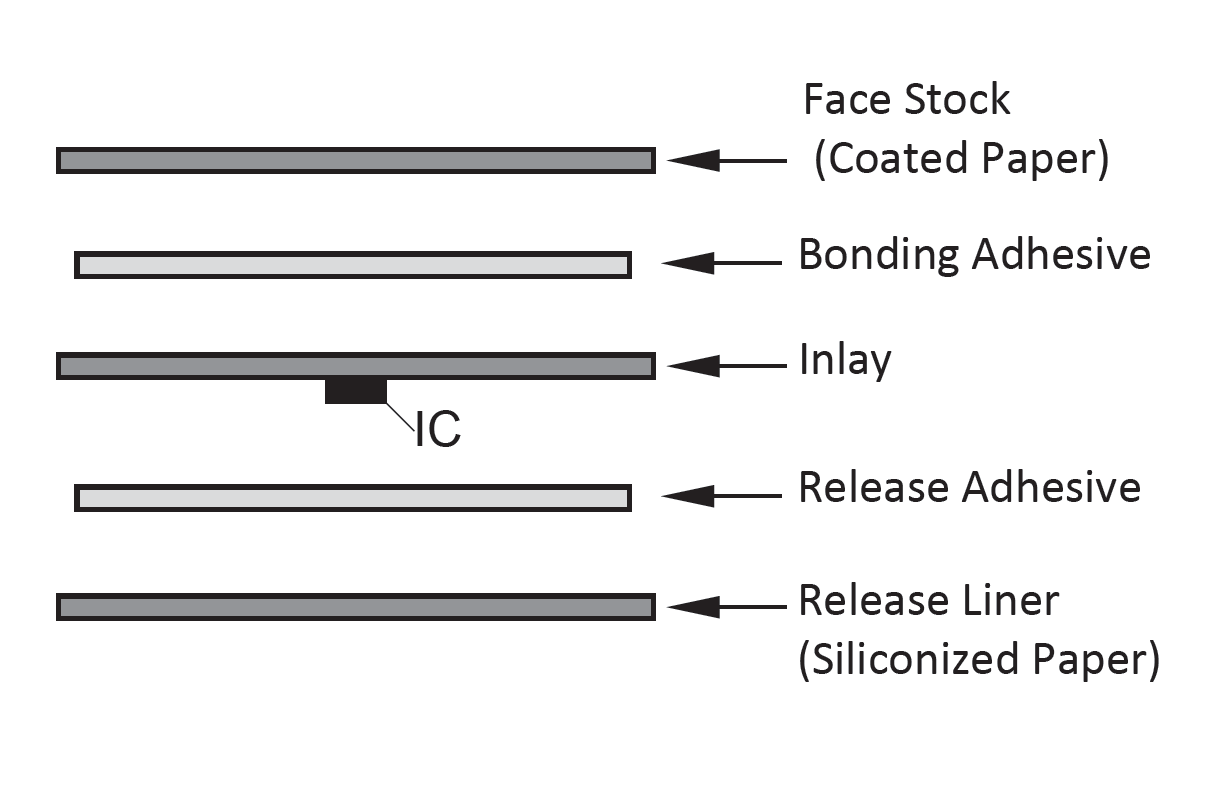

Appearance and Structural Diagram

RFID Tag Layer Structure:

Face Stock (Coated Paper):Top printable layer of the tag,to provide printable surface and environmental protection

Bonding Adhesive: Permanent adhesive for inlay attachment, to secures inlay to face stock permanently

Inlay → Inlay (Industry term - retain original): RFID chip + antenna embedded in substrate,

which contains the RFID IC and antenna (critical functional component)

Release Adhesive: Temporary adhesive for liner backing, which allows temporary attachment to liner

Release Liner (Siliconized Paper): Protective backing paper peeled during application, to enable die-cutting and protects adhesive until use

|

Manufacturer / Chip: |

Impinj/MR6-P or customizable |

Substrate Material: |

PET or Coated paper optional |

|

Compliance Standards: |

ISO/IEC 18000-63(formerly 18000-6C) and EPC Gen2 |

Antenna Fabrication Process: |

Al(10μm) + PET (50μm) → Etched Aluminum (10μm) + PET (50μm) |

|

Operating Frequency Range: |

860~960MHz |

IC Memory Section: |

EPC: 128Bits TID:48Bits Unique TID:48Bits Kill password: 32bit Access password:32Bits User Data: None |

|

Sensitivity: |

-24db |

||

|

Working Mode: |

Passive |

||

|

RFID performance: |

Reading range:0-15m Writing range:0-7m |

Environment: |

Working temperature: -25℃~70℃ Storge temperature: -45℃~80℃ |

|

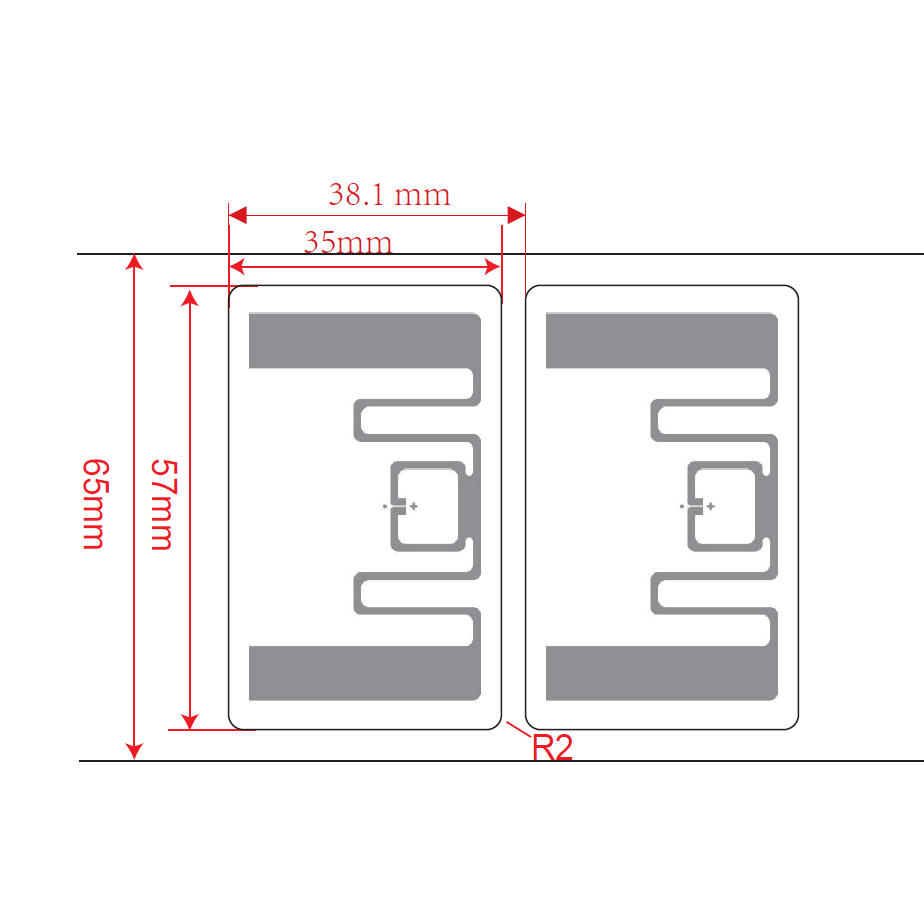

Label Size: |

57*35, 80*50mm, 100*50mm or customizable |

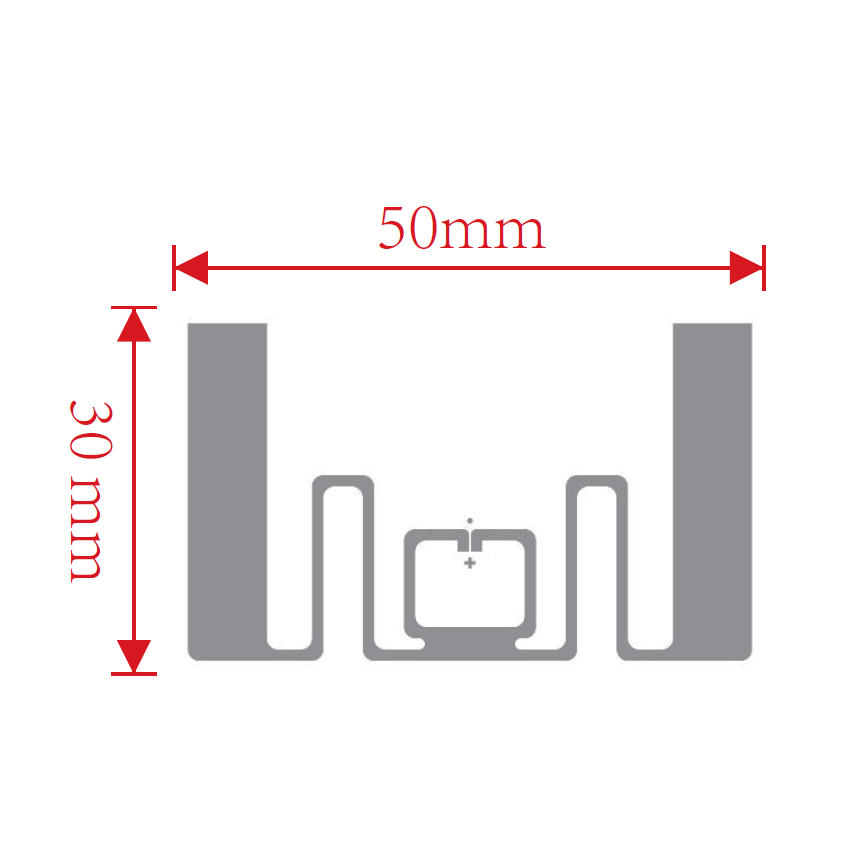

Antenna Size: |

50*30mm |

|

Write Endurance: |

100,000 cycles |

Installing: |

Self-adhesive |

|

IC Endurance: |

Data Retention: 10 years |

Weight: |

≈1g/pcs ≈2Kgs/roll with bag |

|

Polarization: |

Liner polarization |

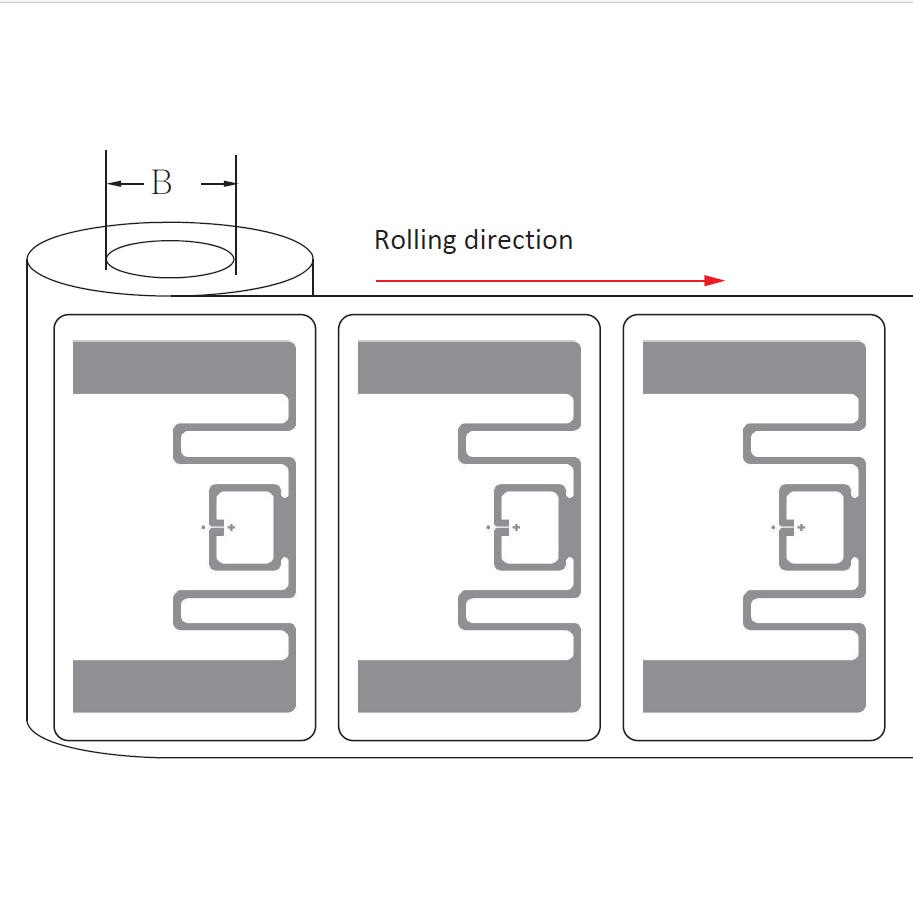

Packing: |

2,000pcs/roll 4 or 8 rolls/carton |

Finished Product Illustration

Winding Specification:

Core Width: 40mm ±1.0mm, Core Inner Diameter: 76.2mm ±0.50mm

Packing

All product cores must be wrapped with ESD foam with shielding layer (as shown below) to mitigate mechanical shock to ICs during transportation.

Tags :