Premium UHF RFID Tags for Industrial Asset Tracking/Warehousing/Logistic

This high peformance RAIN RFID tag delivers industry-leading read range and multi-tag scanning capabilities for high-volume logistics operations. Engineered for standard packaging applications, this cost-effective solution enables touchless shipping verification and automated manifest generation without metal/waterproof requirements.

| Requirement | Solution Embedded |

|---|---|

| Read Range Focus | 6-20m performance (industry top 5%) |

| Multi-Tag Strength | >900 tags/sec (validated with Impinj R700) |

| Non-Metal/Non-Waterproof | Standard PET/paper construction |

| Printer Compatibility | Tested with 15+ industrial printer models |

| Customization | Dimensions/material/adhesive options |

| UHF Standards | Full EPC Gen2 compliance |

Appearance and Structural Diagram

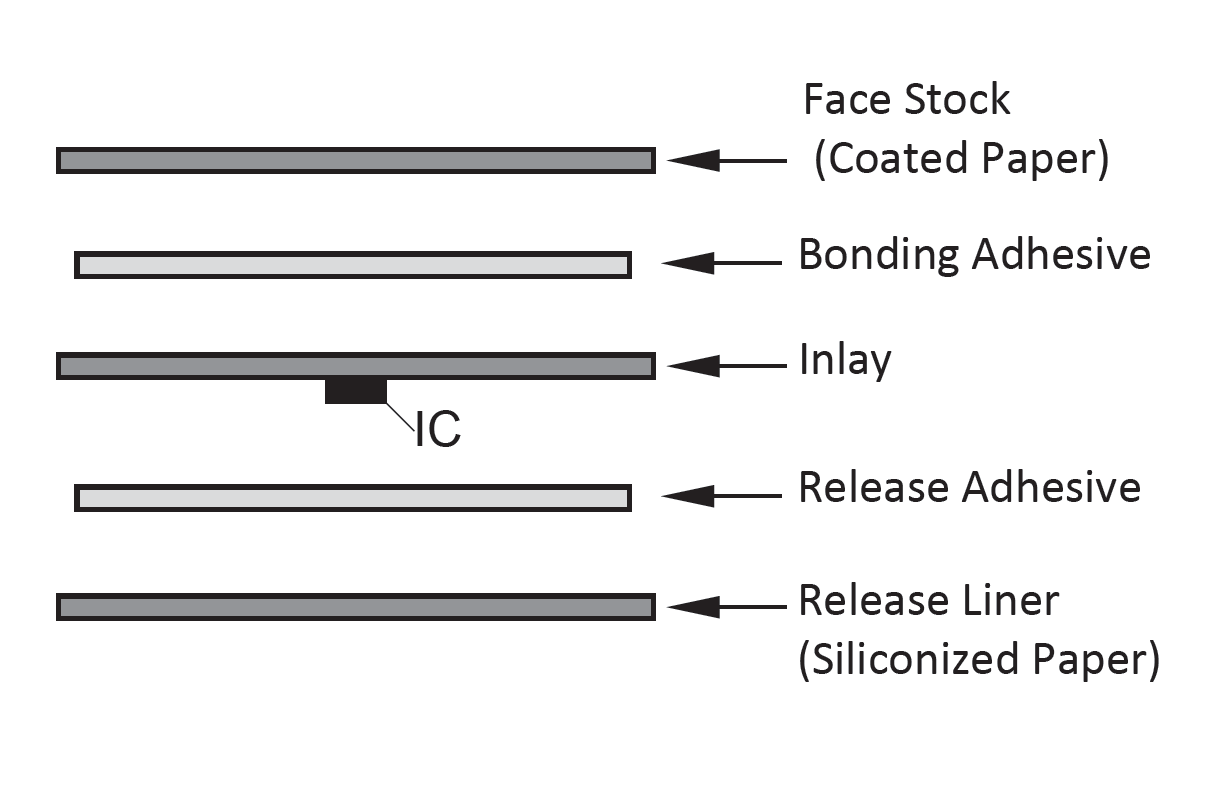

RFID Tag Layer Structure:

Face Stock (Coated Paper):Top printable layer of the tag,to provide printable surface and environmental protection

Bonding Adhesive: Permanent adhesive for inlay attachment, to secures inlay to face stock permanently

Inlay → Inlay (Industry term - retain original): RFID chip + antenna embedded in substrate,

which contains the RFID IC and antenna (critical functional component)

Release Adhesive: Temporary adhesive for liner backing, which allows temporary attachment to liner

Release Liner (Siliconized Paper): Protective backing paper peeled during application, to enable die-cutting and protects adhesive

|

Manufacturer / Chip: |

Impinj/M730 |

Substrate Material: |

PET or Coated paper |

|

Compliance Standards: |

ISO/IEC 18000-63(formerly 18000-6C) and EPC Global Gen2 V2 |

Antenna Fabrication Process: |

Al(10μm) + PET (50μm) → Etched Aluminum (10μm) + PET (50μm) |

|

Operating Frequency Range: |

860~960MHz |

IC Memory Section: |

EPC: 128Bits TID:48Bits Unique TID:96Bits Kill password: 32bit Access password:32Bits User Data: None |

|

Sensitivity: |

-24db |

||

|

Working Mode: |

Passive |

||

|

RFID performance: |

Reading range:0-15m Writing range:0-7m |

Environment: |

Working temperature: -25℃~70℃ Storge temperature: -45℃~80℃ |

|

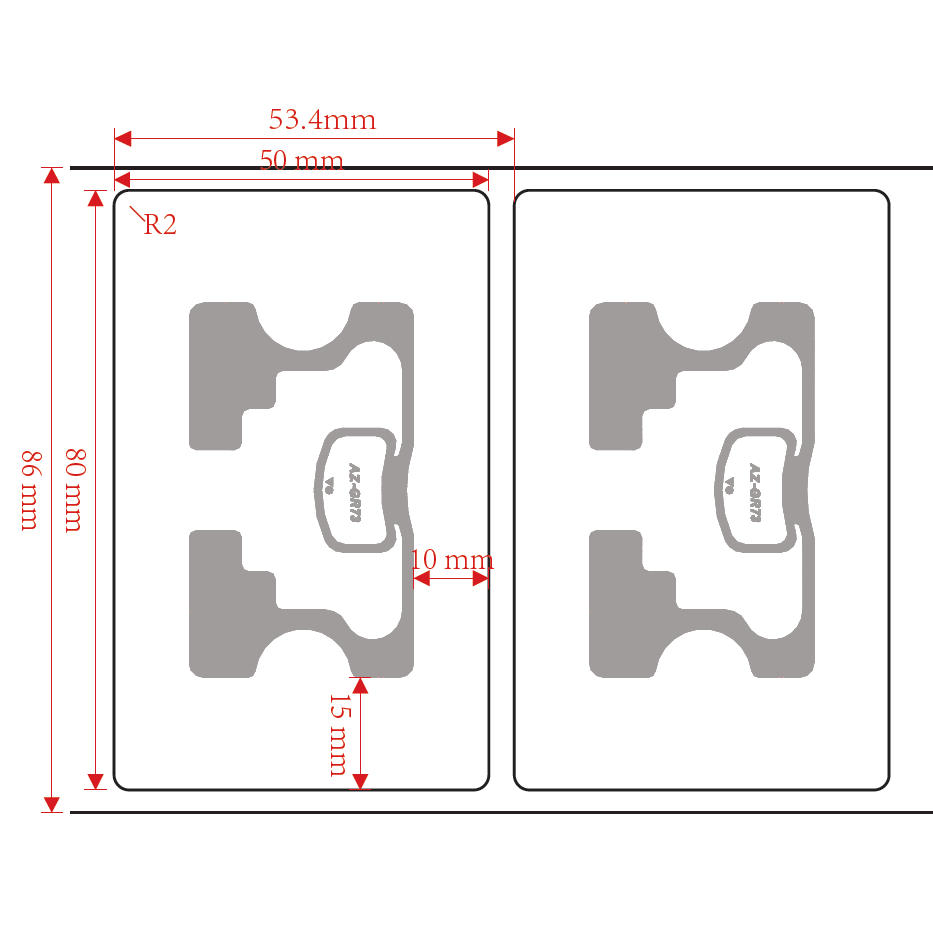

Label Size: |

80*50mm/54*34/60*40mm Or customized sizes |

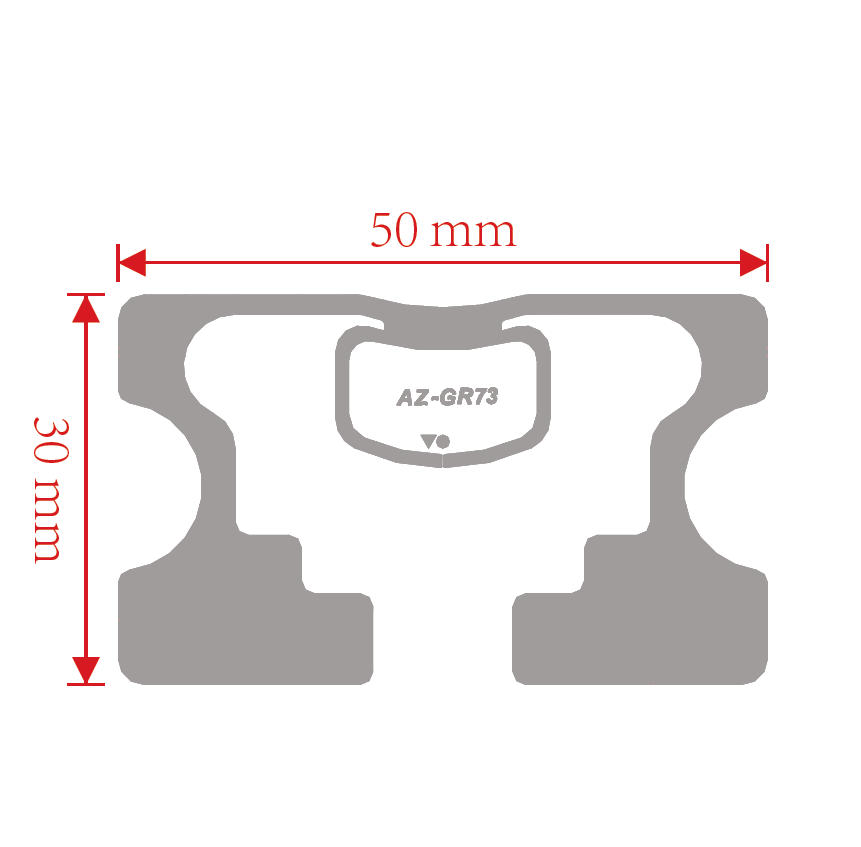

Antenna Size: |

50*30mm |

|

Write Endurance: |

100,000 cycles |

Installing: |

Self-adhesive |

|

IC Endurance: |

Data Retention: 10 years |

Weight: |

≈1.5g/pcs ≈2Kgs/roll with bag |

|

Polarization: |

Liner polarization |

Packing: |

25000pcs/roll 4 rolls/carton |

Finished Product Illustration

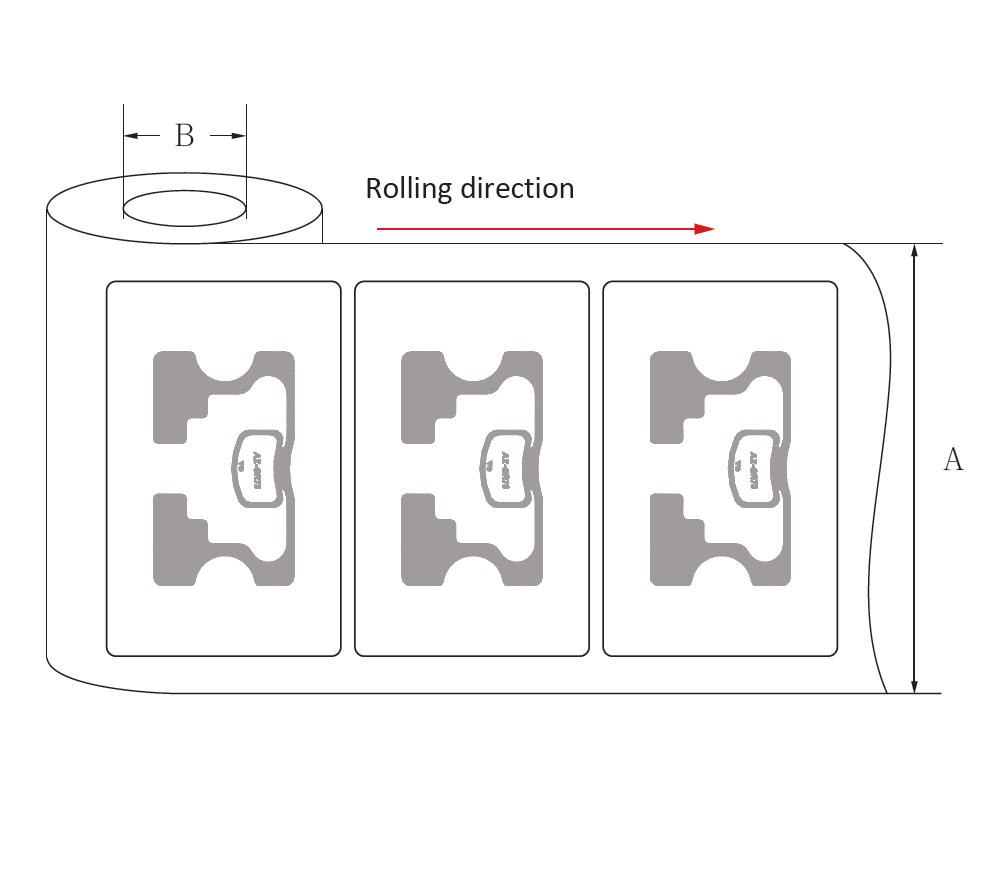

Winding Specification:

Core Width: 40mm ±1.0mm, Core Inner Diameter: 76.2mm ±0.50mm

Packing

All product cores must be wrapped with ESD foam with shielding layer (as shown below) to mitigate mechanical shock to ICs during transportation.