RL8647 Cool Chain RAIN RFID Label

The Cool Chain RAIN RFID Label redefines intelligent cold chain management with cryogenic-grade resilience and embedded thermal intelligence. Engineered specifically for smart retail ecosystems, this tag delivers 99% read accuracy across -40°C to +85°C extremes while featuring anti-frost nanotechnology that outperforms conventional labels by 5X in humidity-controlled environments. Its dual-function design combines GS1 Digital Link-compliant item identification with temperature history logging – enabling real-time perishable inventory optimization, automated FDA compliance, and blockchain-enabled provenance tracking for global supply chains.

Supply Chain Advantages:

✓ -22dBm high sensitivity for pallet-level scanning

✓ Direct thermal printable surface (withstands autoclave)

✓ GS1 Digital Link encoded for blockchain integration

✓ 5-year warranty in continuous freezing environments

Smart Retail Applications:

| Scenario | Value Delivered |

|---|---|

| Frozen Foods | Real-time inventory tracking at -25°C |

| Pharma Logistics | FDA-compliant batch expiration monitoring |

| Fresh Produce | Farm-to-store freshness verification |

| Cosmetics | Anti-counterfeiting in humidity-controlled warehouses |

| Ice Cream | Automated stock rotation alerts |

Engineered for Intelligent Retail Cold Chain Management

Core Technical Features:

Extreme-Temperature Resilience: Operates at -40°C to +85°C (-40°F to +185°F)

Anti-Frost Coating,Freeze-Thaw Cycle Resistant Adhesive : Maintains 99% read accuracy after 100 freeze-thaw cycles

Frozen food packaging Surface Optimized

≥400pcs/second reading + ≥ 6m read range on refrigerated shelves

EPC Gen2v2 & ISO 18000-6C Protocol compatible

Integrated Temperature Logging customziable service optional

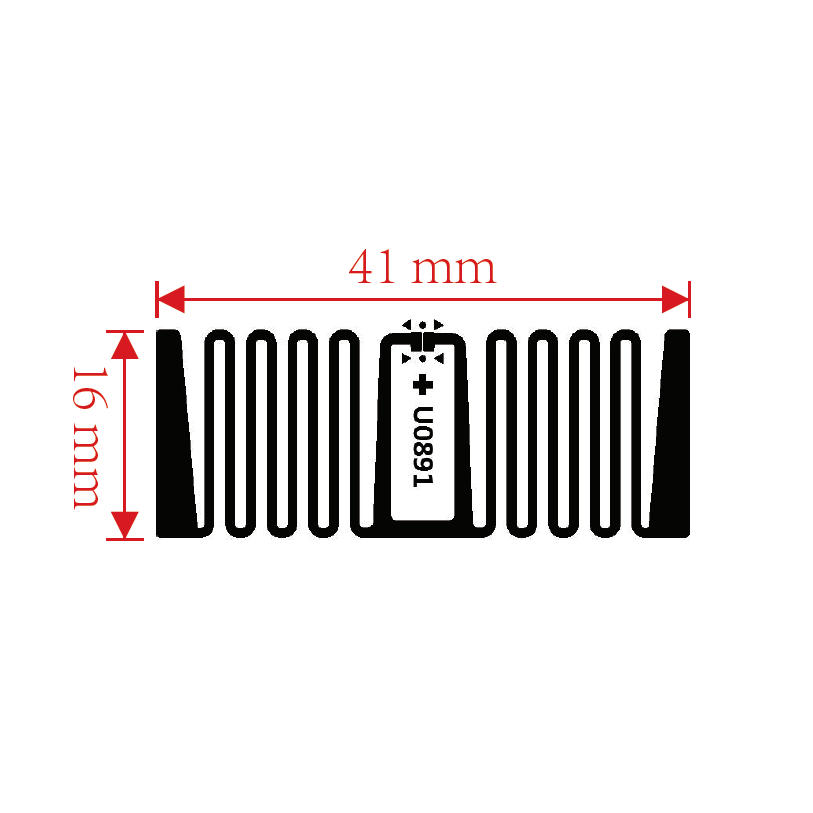

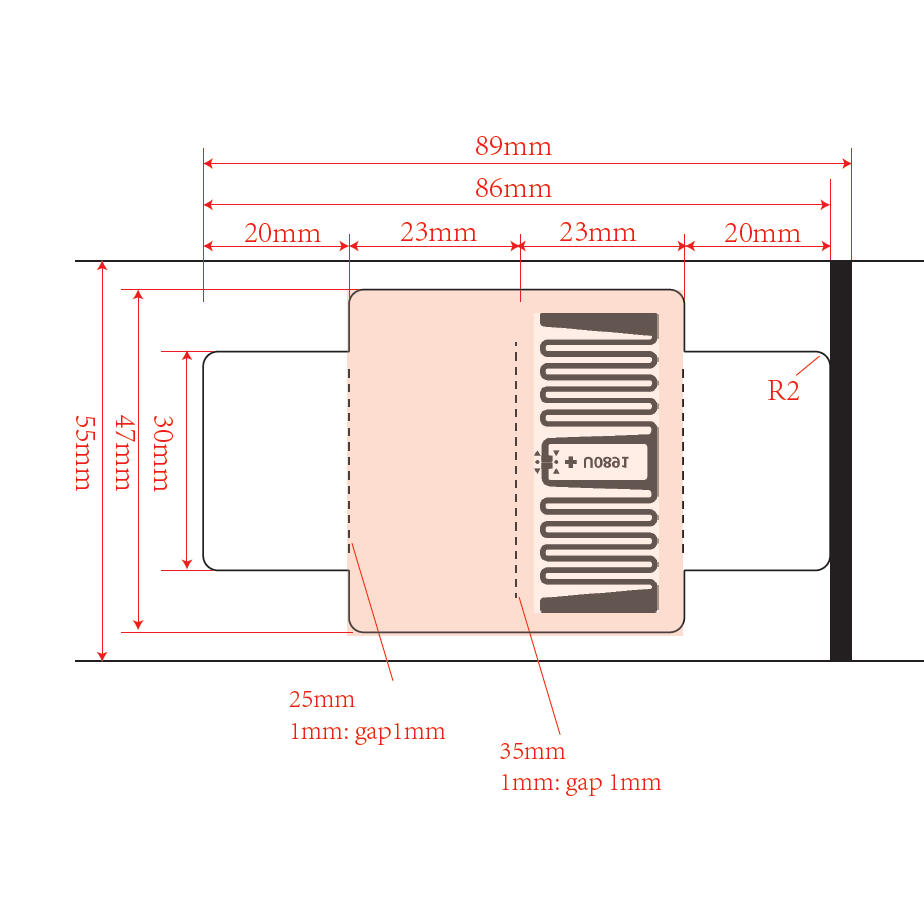

Appearance and Structural Diagram

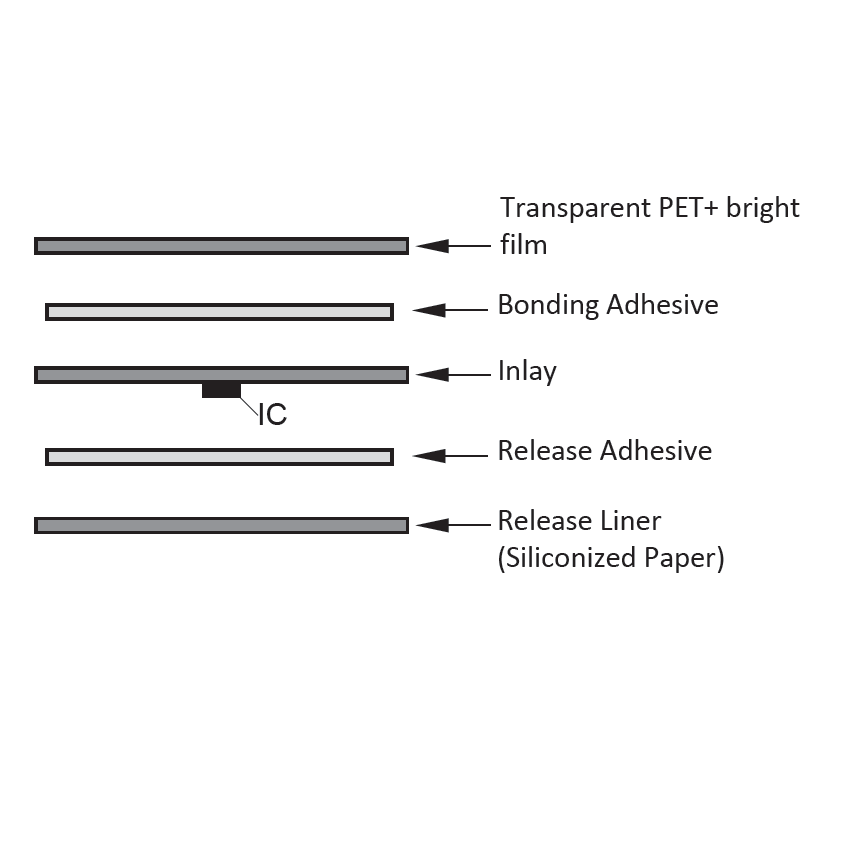

RFID Tag Layer Structure:

Face Stock (Coated Paper):Top printable layer of the tag,to provide printable surface and environmental protection

Bonding Adhesive: Permanent adhesive for inlay attachment, to secures inlay to face stock permanently

Inlay → Inlay (Industry term - retain original): RFID chip + antenna embedded in substrate,

which contains the RFID IC and antenna (critical functional component)

Release Adhesive: Temporary adhesive for liner backing, which allows temporary attachment to liner

Release Liner (Siliconized Paper): Protective backing paper peeled during application, to enable die-cutting and protects adhesive until use

|

Manufacturer / Chip: |

Impinj/MR6-P |

Substrate Material: |

PET |

|

Compliance Standards: |

ISO/IEC 18000-63(formerly 18000-6C) and EPC Gen2 |

Antenna Fabrication Process: |

Al(10μm) + PET (50μm) → Etched Aluminum (10μm) + PET (50μm) |

|

Operating Frequency Range: |

860~960MHz |

IC Memory Section: |

EPC: 128/96Bits TID:48Bits Unique TID:96Bits Kill password: 32bit Access password:32Bits User Data: 32/64Bit |

|

Sensitivity: |

-22db |

||

|

Working Mode: |

Passive |

||

|

RFID performance: |

Reading range:0-6m Writing range:0-3m |

Environment: |

Working temperature: -25℃~70℃ Storge temperature: -45℃~80℃ |

|

Label Size: |

86*47mm |

Antenna Size: |

44*16mm |

|

Write Endurance: |

100,000 cycles |

Installing: |

Self-adhesive |

|

IC Endurance: |

Data Retention: 10 years |

Weight: |

≈1.5g/pcs ≈3Kgs/roll with bag |

|

Polarization: |

Liner polarization |

Packing: |

1,000pcs/roll 4 or 8 rolls/carton |

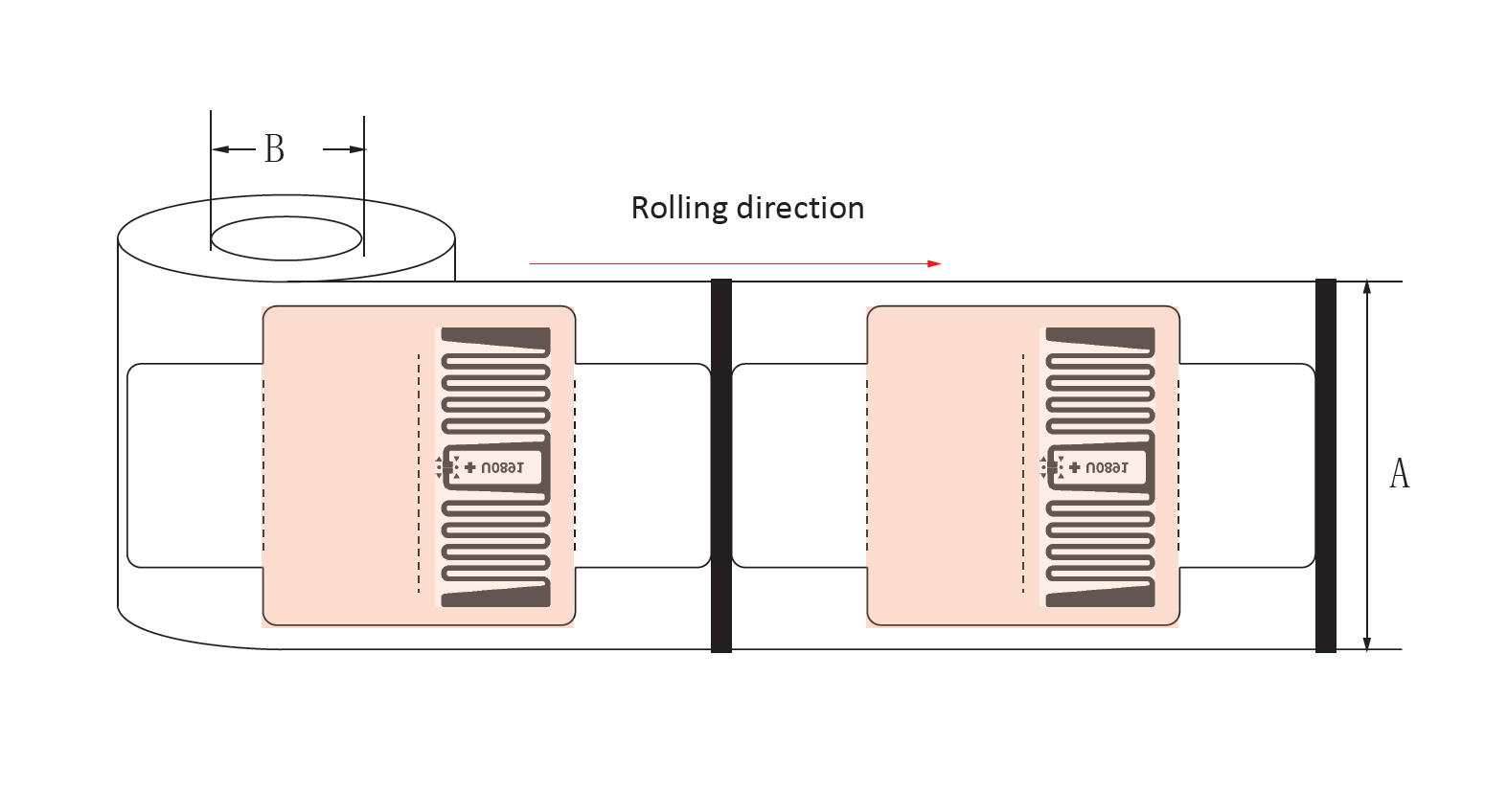

Finished Product Illustration

Winding Specification:

Core Width: 40mm ±1.0mm, Core Inner Diameter: 76.2mm ±0.50mm

Packing

All product cores must be wrapped with ESD foam with shielding layer (as shown below) to mitigate mechanical shock to ICs during transportation.